Industrial Flooring

Trusted Rubber Flooring Solutions

Complete flooring solutions under one roof – Rubber, EPDM, EVA, and Gym Flooring.

Trusted by top industries for over 20 years of excellence in flooring solutions.

We are committed to providing the best quality flooring that combines durability and safety

Get premium flooring solutions at the most competitive prices

Industrial Flooring

Protect Your Floor. Enhance Durability. Save Costs.

We specialize in Heavy Duty Rubber Flooring for factories, gyms, warehouses, and industries where heavy machines, equipment, and material handling can damage the floor.

Unlike Epoxy Flooring, which wears out in short span of time, our Rubber Flooring Solutions are designed for 15–20 years of Service, providing long-term protection at affordable rates.

Why Choose Rubber Matting Over Epoxy Flooring?

Thickness & Strength

Rubber Flooring: 16–18 MM (Heavy Duty)

Epoxy Flooring: Only 2–10 MM (Prone to cracks & chipping)

Durability (Life Span)

Rubber Flooring: 15–20 years (Almost lifetime solution)

Epoxy Flooring: 5–6 years (Needs frequent repairs/replacement)

Cost Effectiveness

Rubber Flooring: One-time investment, last decades

Epoxy Flooring: Cheap initially, but costly in long term due to maintenance & re-application

Weight Bearing Capacity

Rubber Flooring: 50 Kg to 5 Ton

Epoxy Flooring: Not designed for heavy industrial load

Floor Protection & Safety

Rubber Flooring: Shock-absorbent, prevents cracks, reduces vibration, skid-proof

Epoxy Flooring: Can peel off, slippery when wet, weak under heavy impact

Maintenance

Rubber Flooring: No maintenance, no peeling, no re-coating needed.

Epoxy Flooring: High maintenance – needs recoating every few years.

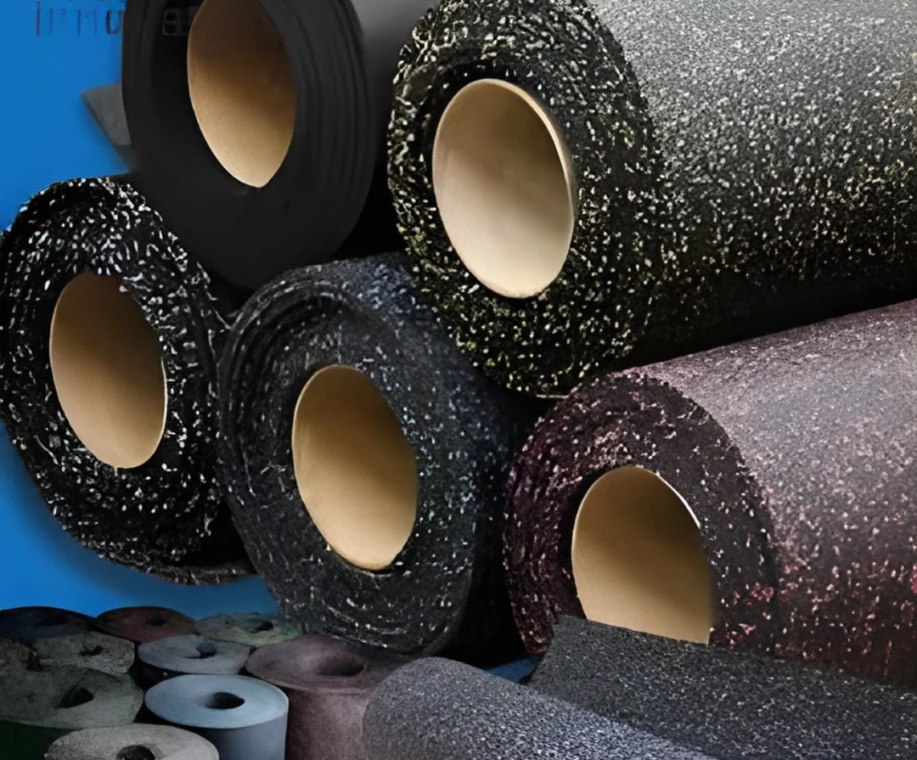

Rubber Flooring

Heavy Duty Rubber Flooring solutions designed for factories, gyms, warehouses, and industrial environments where ordinary flooring fails to perform. In areas with heavy machines, equipment movement, forklifts, and constant material handling, traditional flooring often cracks, wears out, or becomes unsafe over time.

Our Rubber Flooring provides a strong, durable, and resilient surface that protects both the floor and the workforce. It is built to withstand extreme loads, high foot traffic, chemical exposure, and temperature variations without losing its strength.

Unlike Epoxy Flooring, which usually lasts only a few years before needing repairs or replacement, our Rubber Flooring Solutions are engineered for 15–20 years of reliable service, delivering long-term protection, safety, and cost savings.

Silicon rubber sheet

Silicone rubber is a stable, non-reactive elastomer made of silicone (a polymer of silicon, carbon, hydrogen, and oxygen). It withstands extreme temperatures (−55 to 300 °C), ozone, UV, and aging better than organic rubber, while retaining shape and strength. Its durability, flexibility, and ease of molding make it widely used in:-

- Automotive

- Electronics

- Medical implants

- Baby care

- Food-grade products

- Apparel

- Sealants.

Being bio compatible, hypoallergenic, and chemically inert, it is ideal for medical and food-contact applications.

Industrial Flooring For Gyms

EPDM rubber

EPDM flooring can be used for varied purposes ,be it, sports flooring , gym tiles, heavy footfalls spaces or playground solutions. They are elastic, durable, and high on comfort and of course aesthetically pleasing too. Our distinctive playground rubber tiles, available in V-Groove and Interlocking styles, are manufactured to excellent standards, providing protection against injuries while ensuring durability, water resistance, and UV protection. This attention to quality extends to all our sports flooring solutions, from professional courts to recreational spaces.

Electrical Insulation Mats

Electrical Insulation Mats, made from premium rubber and synthetic polymers, provide strong protection against shocks and current leakages. IS 15652 certified, they are widely used in substations, transformer rooms, control panels, and high-voltage areas to ensure worker safety and reliability.

Neoprene

A high-performance industrial flooring solution known for its exceptional resistance to oils, chemicals, heat, and weathering. Designed to withstand harsh working environments, Neoprene flooring provides long-lasting durability, slip resistance, and cushioning, making it ideal for areas where heavy machinery, equipment, or continuous foot traffic is present.

Kota Tiles Flooring Vs Industrial Rubber Flooring

| Parameter for Differentiation | Industrial Rubber Flooring | Heavy Duty Tiles Flooring |

|---|---|---|

| Nature | Hard | Brittle |

| Breakability | Non-breakable | Breakable |

| Thickness | 15-18 MM | 10-12 MM |

| Durability (Life) | 15-20 years (Approximately Lifetime) | 3-4 years |

| Weight bearing capacity | 50 kg to 5 Ton | 50 kg to 500 kg |

| Recurring cost | Nil | Yes. Repair costs are variable based on damage and repeat installation |

| Cost | 📞 Ask On Call | Rs.70-100 /square feet |

| Colour | Black | Variations available |

OUR CLIENTS

Testimonials

FAQs

Why does Industrial Flooring recommend Rubber Flooring over Epoxy Flooring?

At Industrial Flooring, we suggest Rubber Flooring because it is highly durable and long-lasting compared to Epoxy. Rubber Flooring offers up to 15–20 years of service life, while Epoxy tends to wear out faster under industrial use.

Can Rubber Flooring from Industrial Flooring handle heavy machinery and equipment?

Yes, our Rubber Flooring solutions are designed to withstand forklifts, heavy machines, and continuous material handling. They are shock-absorbing and prevent damage to the floor.

Does Rubber Flooring improve safety in industrial environments?

Absolutely. Our Rubber Flooring is slip-resistant and provides better grip even in wet or oily conditions. Epoxy Flooring, on the other hand, can become slippery and unsafe.

How is the maintenance of Rubber Flooring compared to Epoxy Flooring?

Epoxy floors often crack and require frequent repairs. In contrast, Rubber Flooring from Industrial Flooring is low-maintenance, easy to clean, and built for long-term performance.

Why are Electrical Insulation Mats important for safety?

Electrical Insulation Mats protect workers from electric shocks while operating high-voltage equipment, ensuring workplace safety and compliance.

Can Silicone Rubber Flooring handle extreme temperatures?

Yes, our Silicone Rubber Sheets can withstand both high and low temperatures, ensuring performance in challenging environments like factories and laboratories.